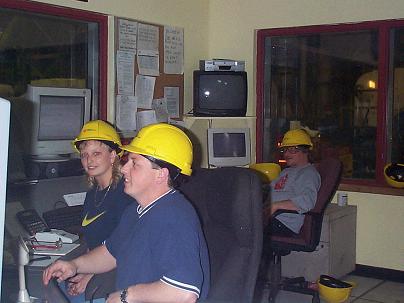

Among several other companies visited by MOT students on their field trip, the group had an opportunity to view operations at Abitibi Consolidated in Stephenville

MOT students experienced their first field trip this year. One company visited by the students was LaFarge Gypsum in Corner Brook